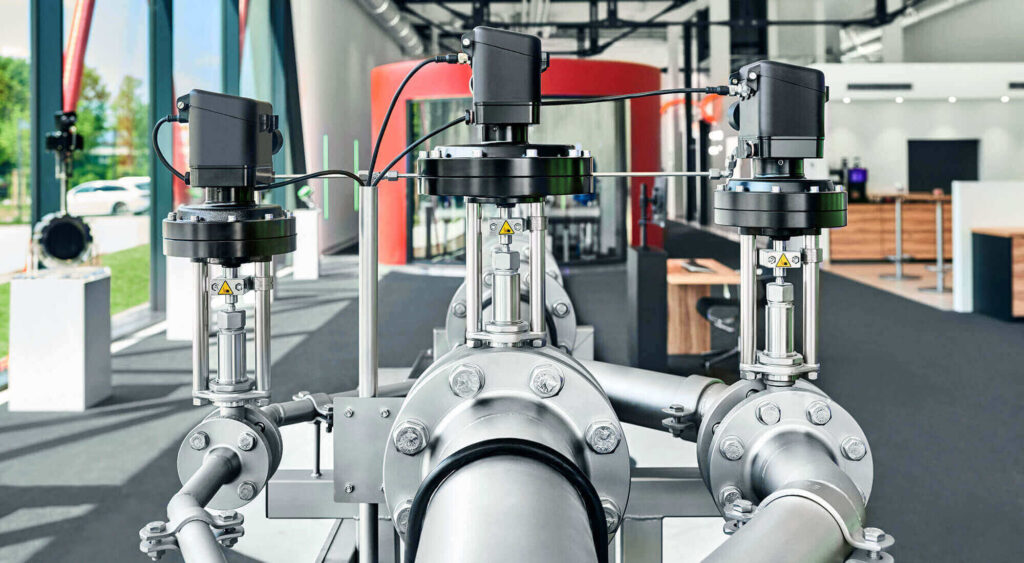

Valve maintenance and lining are essential for ensuring the efficient operation and longevity of industrial systems. Teflon and rubber linings play a critical role in protecting valves against wear, corrosion, and chemical degradation.

Teflon provides superior resistance to harsh chemicals, acids, and alkalis.

Rubber is ideal for abrasion resistance and handling less aggressive chemicals.

Teflon’s non-stick surface minimizes the accumulation of residues, enhancing valve efficiency.

Rubber linings provide a flexible seal, reducing wear from repeated operation.

Teflon can withstand high temperatures, making it suitable for extreme conditions.

Rubber offers excellent performance in a wide range of temperatures, depending on the type.

Teflon Linings: Used in industries such as chemical processing, pharmaceuticals, and food production, where non-reactive surfaces are critical.

Rubber Linings: Commonly applied in water treatment, mining, and slurry handling, offering excellent resilience and sealing capabilities.

Our expertise in valve maintenance and lining ensures you receive top-quality Teflon and rubber solutions tailored to your operational needs. With advanced tools and experienced technicians, we guarantee optimal performance and extended valve life.

Contact us today to learn more about our services or schedule an assessment!

Would you like this tailored further or presented in a specific format?